I blew a diode while pushing the boundaries of my IRF520 output transistors messing around with FT8…

Troubleshooting was actually pretty simple this time as I chose to use technology to my advantage and simply scanned the parts during transmit with the infrared heat gun and found a diode was 25 degrees hotter than everything else around it. This has to be cheating…

Let’s rewind time just a little so you can understand what I have been doing here… You see, this radio came with some fairly fragile finals from the factory. So fragile in fact, that they sent a spare set with the radio. The IRFZ24N transistors were wonderful, but under full load on FT8 and into less than perfect SWR would prove fatal for them. I ended up killing 3 of them before changing my radio over to the V3 spec. The V3 specification changes the finals and also changes a few other components in the amplifier chain to use them properly. HF Signals sent out a bulletin showing what all needed to be done and it was actually pretty straight forward. I decided to use some IRF520 transistors instead of the IRF510 transistors speced for the update as they had better current specs than the IRF510. They are rated for the same power dissipation essentially, but can handle almost twice the current without damage. This combined with the fact that I had them on hand, led to the construction of a bomb proof set of finals in my sBitx radio!

Once I had them installed, I set the bias and was off to the races. They literally handle anything I throw at them and I have run them hard to make sure they would not fail in the field at an activation. This is good and bad you see, these transistors work so well that I now can get over 65 watts (with the drive set to 100%) on 80 meters with them…and this is a problem.

The sBitx is not engineered for transmitter output powers this high, the original design was for 40 watts maximum forward power. and the components in the amplifier chain are sized accordingly. I learned this when I powered up the machine after messing around on 80 meters and accidentally transmitted into a 10:1 SWR with it last night (probably infinite SWR since it was into the coax with no antenna on it... It blew the 10 amp fuse almost immediately, which I figured would protect the radio…and it did, sort of... I was able to put a new fuse in it and get right back on 80 meters without any trouble at all. I didn’t leave that band though so I had no idea what had actually happened.

Fast forward back to today, I turn on the rig and dial up 15 meters to see what was happening on FT8 there, tune up the antenna with the Comet Antenna Analyzer and the manual antenna tuner and I am off to the races! Or so I thought. Seems when it would go into transmit, there was zero watts going out to the antenna, but the Astron RS-35M power supply was showing proper current draw for 15 meters FT8 transmit! How is it pulling the right amount of amps (6 amps is 20 watts on 15 meters) and not putting anything into the coax? That math ain’t mathing… I remember that whole current law about current going in has to match current coming out, so I start looking around.

I tested 10 meters and it was the same, so was 20 meters, but when I got to 40 meters, suddenly I had power to the antenna again. I also had it on 80 meters as well, full output power was there till I left the two lower bands. Something is either wrong with the 80/40 section OR all of the others. So I take it down to the shop where my test bench is located and rig it to a dummy load to see what I could find with the heat gun.

The photo below shows the diode that is shorted where I pulled one leg, so I could test my theory prior to dismantling the radio to replace it properly. This is a 1N4007 and it is being used to switch the radio’s transmitter band pass filters into and out of circuit. It has four filters to cover 8 ham bands (80 & 40, 30 & 20, 17 & 15, then 12 & 10 is the last one). The diode that failed was on the 40 & 80 meter filter. This essentially turned it on all the time. and also turning off the others by putting the switching voltage on both sides of the other filters output diodes. This makes them all have zero volts dropped across them essentially turning them all off. So only the 40 & 80 meter filter could be turned on at this point. You can see what I am talking about by looking at the schematic below where I am pointing out the diode that failed on the print.

The foreground, in the below photo, is the board showing the new diode in place after removing all the stuff in the background to get to it. You have to literally take the whole thing apart to get to this part of the radio. Fortunately for me, I have done it so much I have memorized the process and can do it in maybe ten minutes. You can also see the two IRF520 finals next to my thumb, you can also see all the heatsinks I installed to help mitigate the heat buildup in the radio.

Did a static test on the bench, just to make sure, and it worked perfectly with the dummy load attached. Luckily I did it right and dont have to take that whole thing back apart! HaHa. In the background is another little project I may write about. Seems the sBitx has this systemic problem with low audio on SSB and I tried the new microphone element others in the email reflector suggested to no avail. So the next solve is a more “active” solution with the use of a small single transistor amplifier is a sort of (pre-amp) configuration so that I can increase the audio signal going into the radio and make it actually work like it should. The radio already has one of these circuits in it, I don’t think it can handle any more gain with out distorting so I want to pre-amp into it with a variable gain setup so I can go into it with 2x, 3x or even 5x the input signal so I can get decent audio out of my radio. More on this later…

Man, I had no idea how messy my bench was till I looked at this photo… I will have to clean that up! Sorry about that everyone…

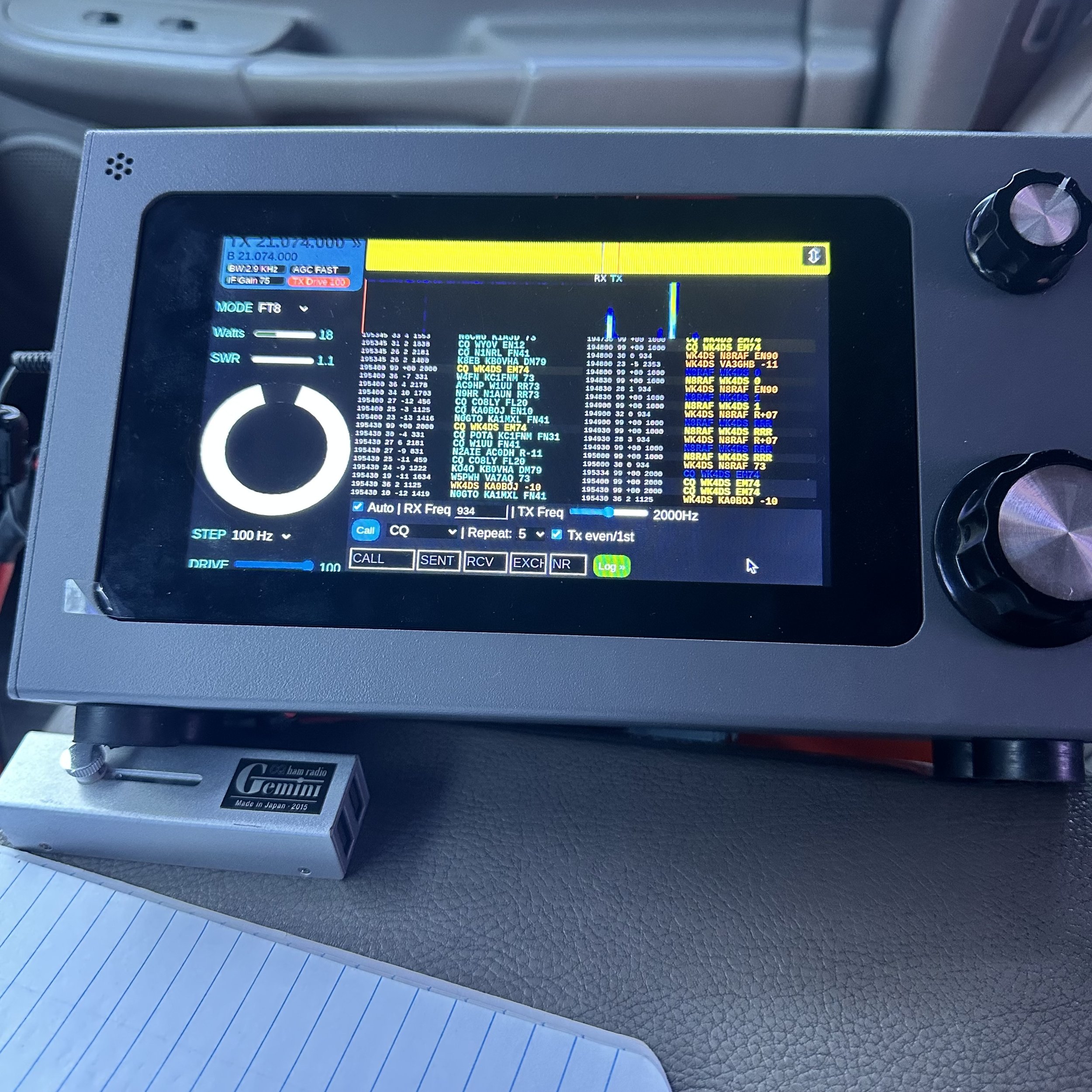

So today had the real test. I took it to US-2169 and setup in my usual spot and decided that today I would stay on 40 meters till I secured the activation then I would move to 15 meters to see what I could find. Seem I found a lot. 40 meters and hamsticks will usually produce contacts that are closer to home for me, maybe as far away as Texas or Michigan is a long haul on 40 meters but 15 meters is a different story all together. With me getting contacts in Russia and Japan on this trip! If you will notice the power levels are lower, this is because the truck, when shut down, has battery voltages around 12.5 VDC and not 13.8 as these are older batteries, well this produces less output wattage since the voltage is lower. Still had plenty to make a ton of contacts with while I was at the park! Of note here, only the FT8 contacts are with the sBitx, all the CW contacts are with the Ten Tec Scout 555 portable radio. I did scan through the 15 meter side band section of the band and heard zero QSOs so that is why I went to CW. There was a station with a mild pileup on CW and so I moved up 5kc or so from them and set up shop there for a while. I was able to get all three west west coast states a Russian, a Canadian, and Massachusetts! Enough about the Ten Tec Scout though, this is about the sBitx…

The sBitx is up and running again and it is all good now. The radio runs flawlessly (other than the SSB audio) and I am happy as a lark now. More to come as they software gets dialed in for better CW operation!